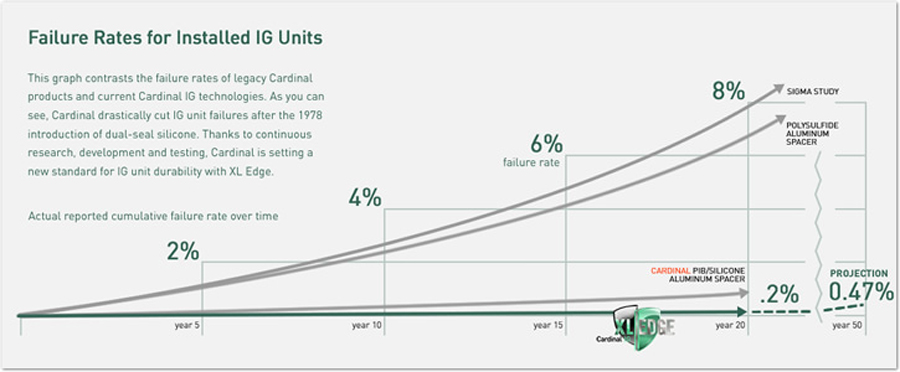

Cardinal IG has used dual-seal polysulfide seal in its units for years. As this chart indicates, Cardinal units produced in 1976 showed a failure rate of 8.5% after 20 years. That’s on par with industry statistics: a Sealed Insulating Glass Manufacturing Association (SIGMA) study reported failure rates for standard IG units more than 9% after just 15 years.

CARDINAL IG EXPERTISE = LOW FAILURE RATES

In 1978, Cardinal IG Company became the first manufacturer to produce dual-seal silicone IG units, drastically reducing IG failures. Cardinal IG units produced in 1978 with dual-seal silicone reported a cumulative failure rate of just one per-cent over 20 years. Contrasted with Cardinal’s 1976 polysulfide dual-sealed IG units, dual-seal silicone reduced IG failures by more than 85%.

In 1993, Cardinal introduced XL Edge™, a revolutionary IG unit combining a dual-seal silicone system with patented stainless steel – rather than aluminum – spacers. XL Edge is the most durable IG unit available today. Based on a decade’s worth of experience, we project that the failure rate for Cardinal IG with XL Edge over 20 years will be well below 0.5 percent.

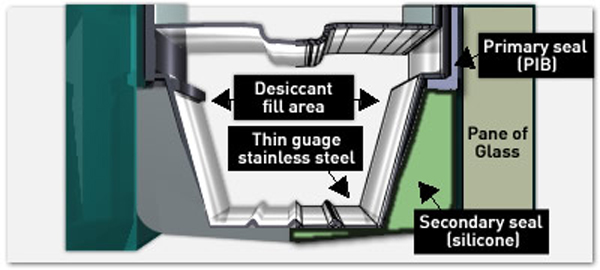

We provide a 20-year guarantee on XL Edge units because of Cardinal’s advanced design and fabrication. XL Edge is at the leading edge, incorporating a stainless steel spacer with airtight bent corners and a dual-seal construction of compressed polyisobutylene (PIB) and silicone. Desiccants are contained in the spacer to eliminate any potential for moisture. Argon is filled inside the IG unit, improving window U-factor. Since XL Edge is a warm-edge IG, the possibility of indoor condensation is greatly reduced.

Cardinal’s superior IG construction translates into a 0.2% seal failure rate over twenty years – plainly the lowest in the industry. To compare, the well-established 1976 Sealed Insulating Glass Manufacturing Association (SIGMA) study identifies average industry IG failures of over 9% in fifteen years. Modern competitive spacer systems simply cannot match the long-term durability characteristics of XL Edge IG. Even older Cardinal technologies, like IG with aluminum spacers and polysulfide or PIB, didn’t stack up against XL Edge.

Its insulating capability improves the window U-factor by as much as 0.03 compared to an identical configuration using an aluminum spacer. Whether you use ordinary clear glass or advanced glazing products like LoĒ³, XL Edge IG provides better thermal performance. These benefits make a difference in compliance with local energy codes.

The warm-edge characteristics of XL Edge IG reduce the frequency and amount of condensation during the most extreme temperature conditions. For a vinyl window design, it would have to be -11°C colder outside before condensation forms on a unit with XL Edge in comparison with aluminum.